Quality

Policy

Senior Flexonics - GA Precision is committed to achieving complete customer satisfaction by providing high quality precision components and assemblies on time, which meet or exceed customer requirements.

We will utilize the Quality Management System to drive continuous improvement of our processes to ensure satisfaction of both internal and external customers, while achieving sustainable growth of the business.

Standards

Senior Flexonics - GA Precision is experienced in quality requirements specific to aerospace, automotive, and other industrial markets, and is registered to AS9100 Quality Management System standards.

Team

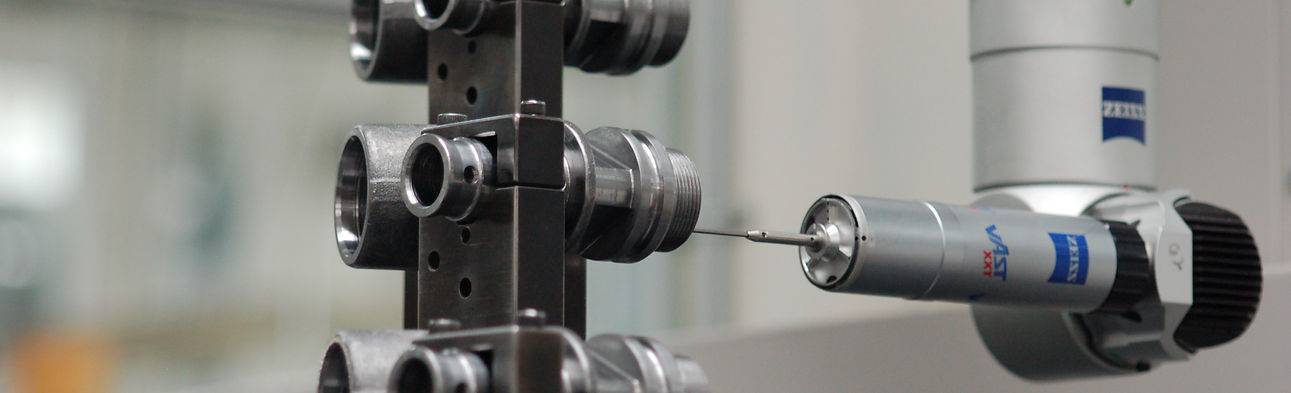

The Quality Team at Senior Flexonics - GA Precision is composed of a fully staffed, 24-hour per day Quality Lab providing real time data and support to manufacturing, CMM Programmers, an on-site Metrology Department supporting NIST traceable calibration, and a Quality Engineering group supporting Advanced Product Quality Planning (APQP), data analysis, customer documentation, customer specific requirements, and problem solving.

Quality Lab capabilities include:

-

6 Zeiss CMMs, 4 with RDS articulating heads and 2 with fixed heads, all are full scan heads and all have programable probe changes

-

Zeiss Surfcom - Surface Profile, Contour, and Form analyzer

-

Talysurf Surface Analyzer

-

Zeiss Rondcom – Form Tester for roundness, cylindricity, runout, and surface texture

-

Zeiss O-Inspect with probe and optical measurements Critical burr control inspection capabilities include high magnification microscopic inspection, and borescopic inspection.

-

Part cleanliness quality monitored using Millipore testing equipment with gravimetric (weight) results.

-

Alloy grade and chemistry verification conducted using hand held XRF (X-Ray Fluorescence) technology to ensure material/alloy control.

-

Brinell hardness testers and Rockwell hardness testers (Hardness A, B, C scales or 15N, 30N or 45N scales) for monitoring of raw materials, castings, forgings, heat treat hardness verification, and case-hardened and through-hardened parts.

-

Statistical Process Control (SPC) is deployed throughout the production process to ensure process capability and support continuous improvement.

Certificates

AS9100